- Home

- About Reison

-

Brands

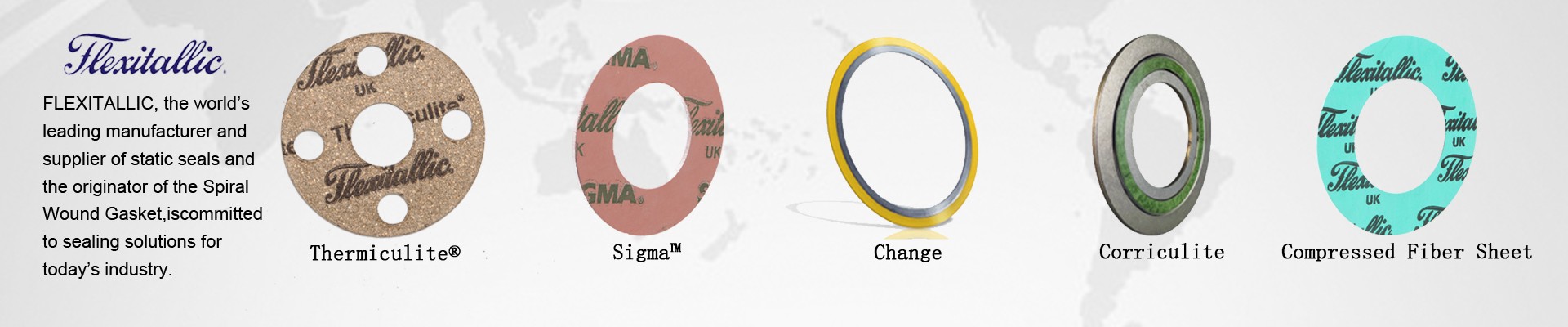

- Flexitallic

- Chesterton

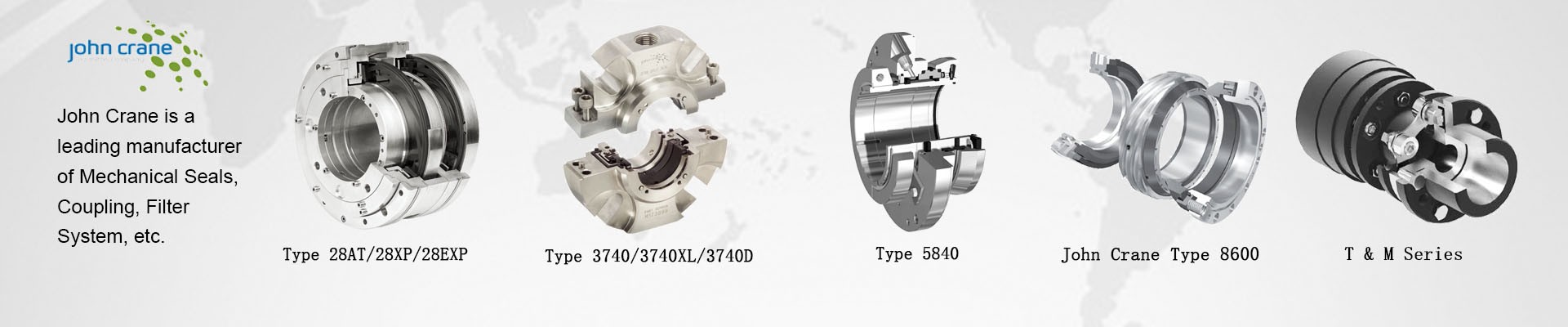

- John Crane

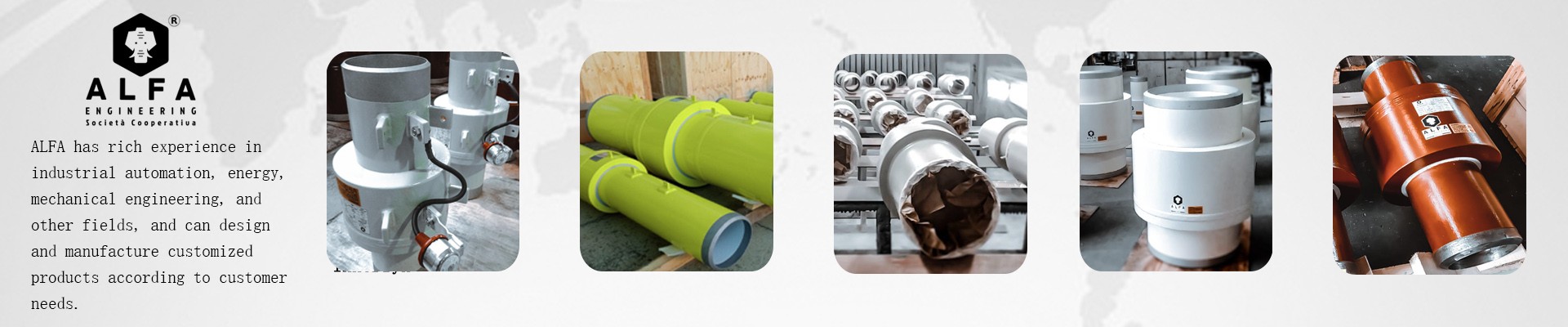

- ALFA

- Mubea

-

APS

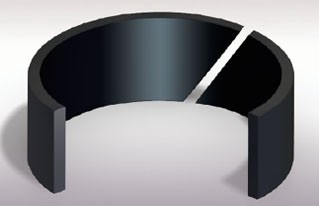

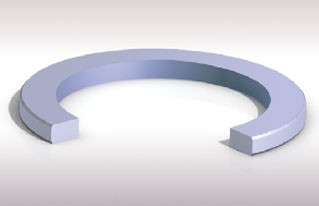

- CASING SPACERS & END SEALS

- INNERLYNX®

- Flange Isolating Gasket Kits

- Flange Band Protectors

- UBolt-Cote® Pipe Supports

- IsoJoint

- Meter Service Fitting

- Safety Spray Shields

- DuoCon Centralizers

- Radolid® Bolt and Nut Protection Caps

- Wall Sleeves

- Hammer & Pile Cushion Pads

- Inspect-A-Lift®

- Raq-Gard®

- Maloney/Foreman Nite Caps

- Katy Spring

- Other Products

- Technical Support

- News

- Contact

- EN

- 中文

- Home

- About Reison

-

Brands

APSCASING SPACERS & END SEALS INNERLYNX® Flange Isolating Gasket Kits Flange Band Protectors UBolt-Cote® Pipe Supports IsoJoint Meter Service Fitting Safety Spray Shields DuoCon Centralizers Radolid® Bolt and Nut Protection Caps Wall Sleeves Hammer & Pile Cushion Pads Inspect-A-Lift® Raq-Gard® Maloney/Foreman Nite Caps

- Other Products

- Qualifications&Honors

- Technical Support

- News

- Contact