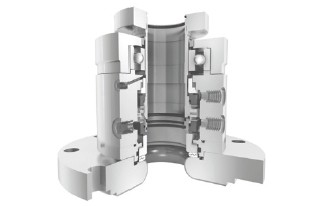

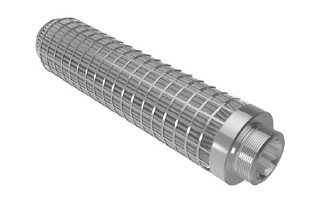

John Crane filtration solutions and technologies, built on the globally-renowned reputation of the Indufil and Seebach brands, keep your operation running at peak performance and avoid the costly effect of contamination. The Indufil brand for equipment filtration systems and elements can extend the life and operational predictability of your critical rotating equipment in seal gas, fuel gas and liquid fuel, and liquid filtration applications. Seebach filter elements and filter systems have been made in Germany since 1970. All Seebach products use stainless steel, glass fiber and polymer filter media. We offer tailor-made designs with precision manufacturing, that outperforms competitor products with longer lifetime and more efficient performance. Our design offers continuous process optimization and innovation for challenging filtration applications in polymer, mining, chemical, food and beverage, aerospace and pharmaceutical industries.