Advance Flange Isolation Gasket Kits are manufactured according to ANSI B16.5 specifications up to 24". Above 24", please provide the specifications of your flange using our convenient worksheet. Technical assistance is available upon request.

TYPE D

Type D gaskets are specifically designed to fit into the ring groove of ring-type-joint flanges. They are manufactured of a medium weave, fabric-reinforced phenolic material and are sized to ANSI specifications available in basic oval as well as octagonal shape. Also available are BX gaskets with pressure ratings to 15,000 PSI.

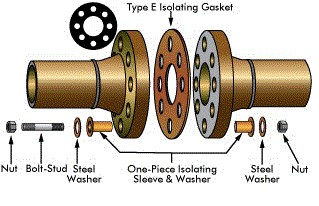

TYPE E

Type E is a full-faced gasket with the same outside diameter as the flange and precision cut bolt holes. This design facilitates proper alignment of the gasket during installation and foreign material prevented from shorting the flange isolation. Type E gaskets are available in plain face or Nitrile faced phenolic, as well as a variety of high temperature materials. Standard thickness of 1/8".

TYPE F

Type F gaskets are made to fit the raised face portion of the flange only. As there are no bolt holes in the F gasket, the inside diameter of the bolt hole circle is slightly smaller than the outside diameter of the gasket, assuring an exact, automatic positioning of the gasket. Type F gaskets are available in the same materials as the type E gasket. Standard thickness of 1/8".

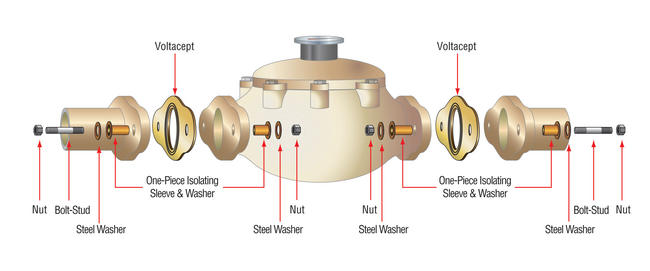

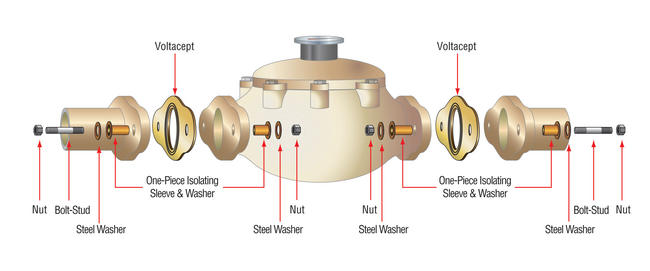

Voltacept™ Trojan

Voltacept™ Trojan G-10 cathodic water meter isolating gaskets are NSF-61 approved and state of the art in near zero leakage static sealing for use in preventing galvanic reaction from the use of dissimilar metals on water piping such as steel or cast iron to brass. The elastomer sealing element is encapsulated in the electrically isolating retainer. The encapsulation of the sealing element permits only microexposure of the seal to potable water flow. G-10 Gasket Kits are designed to keep any and all electrical currents from running back to the water meter.

Gasket Retainer Specifications

|

Name Grade

|

Water Absorption %

|

Tensile Strength PSI

|

Compression Strength PSI

|

Dielectric Values VPM

|

Max Continuous Operating Temperature

|

Flexural Strength

|

|

CE

|

2.00

|

11,000

|

34,000

|

550

|

257 °F

|

125 °C

|

17,500

|

|

G-3

|

2

|

42,000

|

76,000

|

375

|

347 °F

|

175 °C

|

55,000

|

|

G-7

|

0.19

|

25,000

|

40,000

|

350

|

428 °F

|

220 °C

|

18,500

|

|

G-10

|

0.10

|

40,000

|

66,000

|

800

|

284 °F

|

140 °C

|

65,000

|

|

G-11

|

0.20

|

43,000

|

63,000

|

900

|

356 °F

|

180 °C

|

80,000

|

|

XPN

|

1.50

|

18,000

|

45,000

|

600

|

266 °F

|

130 °C

|

29,000

|

|

XP

|

1.50

|

18,000

|

45,000

|

600

|

266 °F

|

130 °C

|

29,000

|

ISOLATING SLEEVES AND WASHERS

Isolating sleeves manufactured in various materials, as well as sizes, are available to meet every customer’s needs. Also available are one-piece integral sleeves and washers which are made of Minlon, providing superior compression strength. Integral sleeves are available in sizes through 1-1/2”. A variety of high temperature sleeves are also stock items.

With each isolating washer, an S.A.E. electroplated steel washer is provided to protect the isolating washer from damage by the nut. Advance flange isolation sets are available in single or double washer kits.

TROJAN SEALING GASKETS

Trojan gaskets are state-of-the-art in near zero leakage static sealing. The elastomer sealing element is encapsulated in the electrically isolated retainer. The encapsulation of the sealing element permits only microexposure of the seal to hostile environments of fire, chemicals and corrosive fluids.

The controlled confinement of the elastomer sealing ring within the retainer allows for the availability of a 92% to 94% volume filled groove. A consistent controlled pressure seal can always be obtained without tremendous bolt loads. Reduced loads allow for reduced flange thickness with smaller circles and smaller bolt holes.

The cross section of APS’ Trojan Sealing Gasket shows the elastomer sealing element as it appears before compression between flanges. This compression causes the seal to effectively fill the void of the groove and encapsulate, permitting only micro exposure of the actual seal to hostile elements either from within or without.

DUPLEX SEAL TROJAN

Four seals on the new Duplex-Seal Trojan further insure the integrity of the sealing capability of an already proven reliable gasket. For areas where absolute zero leakage is a must, the Quad-Seal Trojan works twice as hard.

ADVANTAGES OF THE TROJAN

•Can be utilized with mismatched flanges

•Can be utilized with misaligned flanges

•Can be used in place of RTJ or BX rings

•Little initial torque required

•No re-torquing required

•Sealing ring cannot be left out

•Seal design tested for high pressures

•Reusable

•Competitive price

•Limited area of seal exposed (long fire life)

•Compensates for pressure fluctuations, compression changes, vibrations, temperature, variations, etc.

•Greatly reduces human error during installation

•Large selection of materials available

•Three to four times the dielectric strength necessary

•Low installation and maintenance costs

•Gaskets through 144"